Hinged boxes drilled with holes for wire access are an example of plastic enclosures; such boxes are often suspended from the sides of buildings and allow access to telecommunications equipment by technicians.

Plastic remote controls are an example of plastic enclosures; they are first fabricated and then fitted with circuitry and plastic or rubber buttons. Plastic enclosures can be video game controllers, computer enclosures and electrical component housing. Read More...

Welcome to Pyramid Fab and Finish, where we specialize in providing high-quality electronic enclosures and comprehensive sheet metal fabrication solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients'...

We are committed to excellence and our innovations in enclosure technology is an example of our commitment. Our unparalleled electronic enclosures are specialized for various tasks and our facility is ISO 9001:2008 certified & RoHS compliant. Our superior units come with full customer support. For value-added experience you can rely on us to give you a fair price. We are excited to hear from you! ...

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate and deliver products that others can't. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets, and racks for a wide...

More Plastic Enclosure Manufacturers

They can house televisions, wireless Internet routers, calculators, motors, coolers and an extensive variety of other industrial, commercial and consumer products. Plastic enclosures offer some features that metal enclosures cannot.

They are highly customizable and can be molded into a greater variety of shapes than metal. They can be more lightweight, less electrically conductive and better insulated than metal enclosures. Their lightweightness makes them especially useful in the construction of portable electronics like laptop computers.

Plastic enclosures keep electronic components together and prevent them from becoming contaminated by dust or damaged by impact.

A wide variety of plastic materials are available for the fabrication of plastic enclosures. For sturdier applications, high-density polyethylene (HDPE) is often used because of its strength, durability, resistance to extreme temperatures and its relative low cost.

Other sturdy plastic materials like PVC and ABS may also be used in the construction of sturdy plastic enclosures. Each of these different materials has one thing in common: the method by which they are formed into usable enclosures. HDPE, PVC and ABS are all thermoplastics, which means that they can be formed when subject to high heat.

The thermoplastic forming method most commonly used to create plastic enclosures is molding. During molding processes, a collection of raw plastic stock is gathered and heated to its melting point. At this point, molding methods deviate from each other slightly.

During injection molding, the plastic can be injected into a mold cavity, which is a shape designed to be filled with molten plastic in order to give the plastic its shape. In blow molding the process is similar, except that compressed air is blown into the cavity to make the inside of the plastic become hollow.

In both methods, after the formation process is complete, the plastic is allowed to cool and harden, after which it is ejected from the mold as newly-formed plastic enclosure parts.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

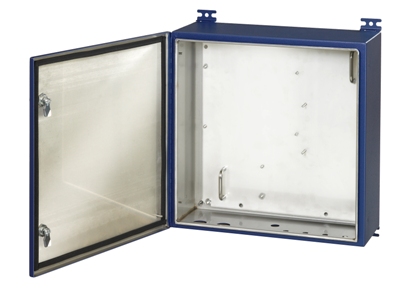

Electronic Connectors Electronic Enclosures

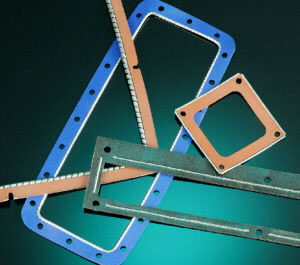

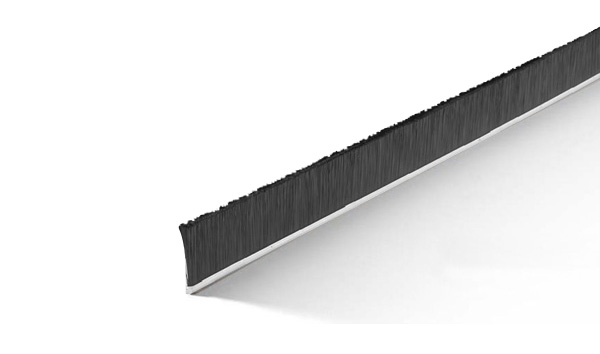

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services