There are indoor and outdoor electronic enclosures, and they are used to protect their contents from dust, dirt, dripping water, rain, sleet, snow and ice formation according to the type of enclosure. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

ROLEC Enclosures Inc. is a leading manufacturer of electronic enclosures. We work without clients’ needs and requirements to find the best solution for them. We also make fully customized enclosures to be ready for use immediately. Give us a call today learn how ROLEC Enclosures can help you will all your enclosure needs.

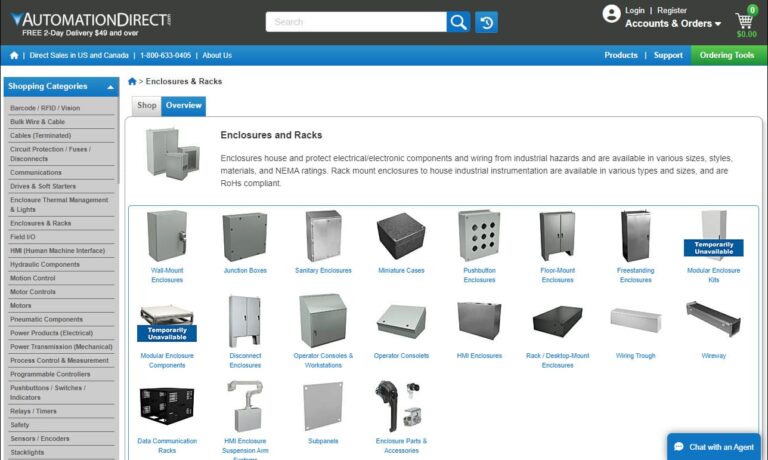

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

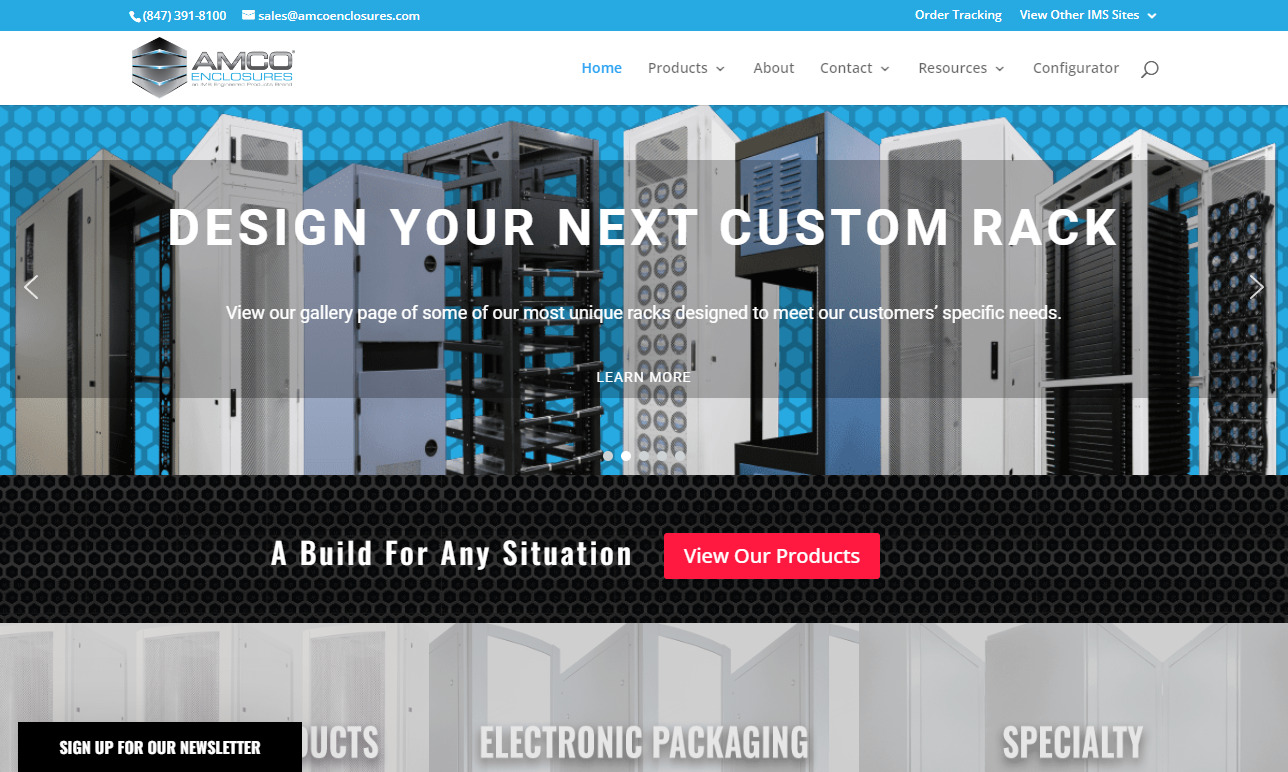

With over 80 years of collective expertise, AMCO Enclosures stands as a pioneer in crafting and delivering top-notch electronic enclosures. Our forte lies in electronic packaging, server rack, network rack, and containment manufacturing, making us the go-to choice for diverse industries.

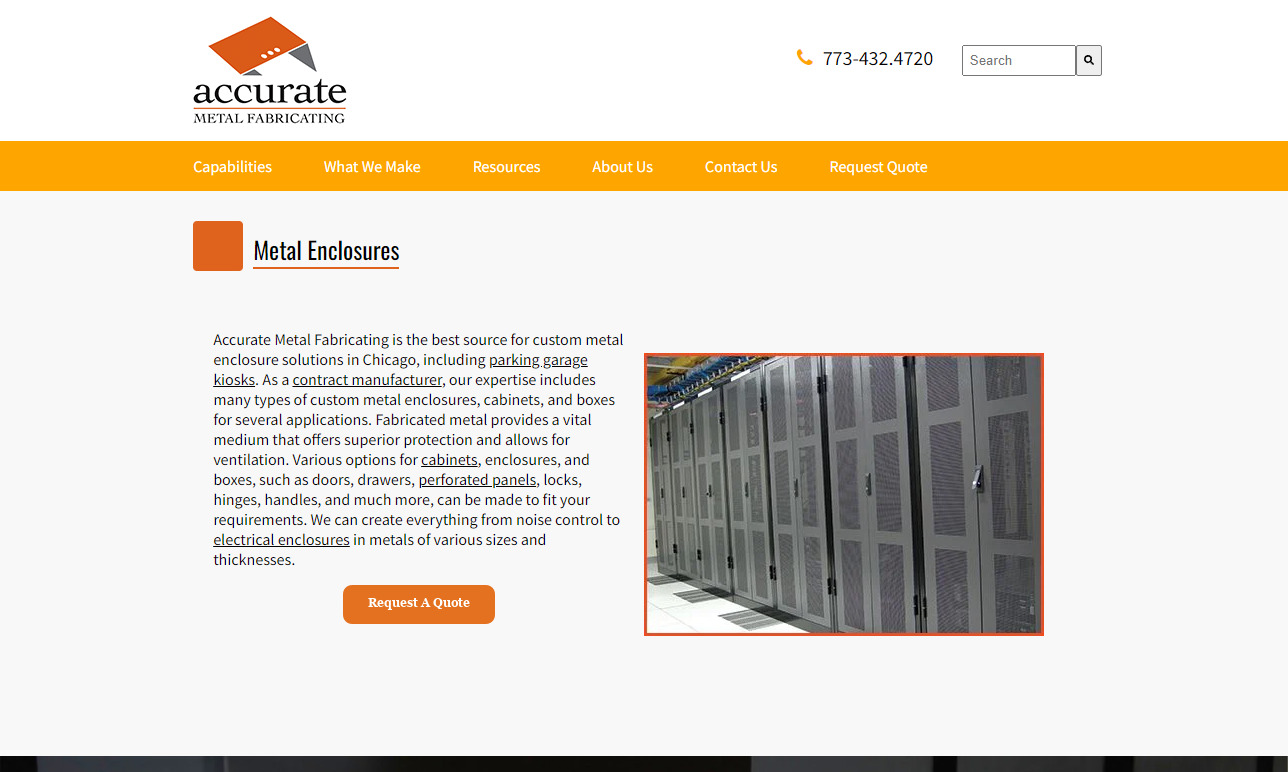

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Fibox Enclosure Systems is one of the largest enclosure manufacturers in the world and is the market leader in thermoplastic enclosures used for protecting electrical and electronic components in hostile and hazardous environments. Fibox recently celebrated over 40 years as a designer and manufacturer of thermoplastic enclosures. Besides pioneering polycarbonate enclosure products, Fibox has...

SPM manufacturers a wide range of NEMA rated electronic enclosures. We are certified by UL to manufacture and sell various enclosure types such as 1, 3R, 4, 4X, 12K, and 13. Each type or rating is manufactured and tested to provide a degree of protection against certain environmental conditions per the standards of UL and NEMA.

More Custom Enclosure Manufacturers

Electronic enclosures are generally box-like in shape but custom-made enclosures tend to have more variety because customization allows curves, contours and complex shapes that otherwise are not available.

Generally, aluminum, stainless steel or galvanized steel are used for their strong and durable properties. Some enclosures are made from plastic because it is easier to work with when creating small or complicated enclosures.

Though the range of applications is broad, there are 5 basic categories of enclosures. Portable enclosures are small enough to fit in a pocket or be held in a hand, like a remote car starter. They may incorporate a battery compartment or LED.

Desk top enclosures can be customized with foot pads, removable stands and engraving. Boxes with clear windows and touch screens are common display enclosures that can be adjusted for size and mounting configuration. Wall mounted enclosures can be customized to make installation and access easier while maintaining security and safety. Lastly, cabinet enclosures usually house standard 19 inch audio and video equipment or computers but can be modified to fit virtually any need.

Custom enclosures are necessary when readymade enclosures are the wrong size, shape, material or finish. The electronic industry (or any industry that uses electronic equipment) is constantly making innovations and developing new technology that requires new housings in order to maximize space and minimize costs. The process of customizing enclosures begins with design and product engineering.

A punch, mold or die is created, depending on the material, and the product is formed. Plastic or composite materials can be molded or punched. Some metals are cold-rolled into sheets then spot or seam welded; others are cast or extruded. Extrusion forces a bar of steel or aluminum through a die and is used when complex cross sections are required. Knockouts and openings are cut and removed, and vents are added if necessary.

The enclosure is then cleaned and deburred to leave a smooth surface. Some receive a finish such as powder coating, enamel or silk-screening or may be left plain, depending on the aesthetic requirements.

The enclosure is assembled and given its final hardware and accessories, which can include handles, slides, shelves, panels, drawers, fans, blowers, power strips, wire management, doors and more.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

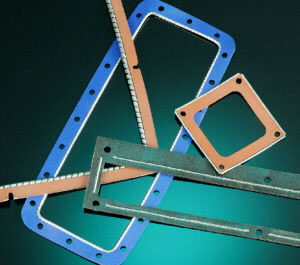

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services